Smoke Ventilation Window Actuators

Window automation plays an essential role in ensuring the safety and efficiency of modern buildings, both in terms of natural ventilation and smoke evacuation in case of fire. While daily ventilation requires controlled opening and moderate reaction time, smoke ventilation windows impose much stricter requirements, established by the European standard EN 12101-2.

In addition to window automation for ventilation, smoke ventilation window actuators must have, according to the European standard EN 12101-2, additional performance:

- Temperature resistance (30 minutes, at 300 degrees Celsius);

- Reliability testing – at least 1000 open-close cycles if they only perform smoke ventilation and at least 10,000 cycles if they also perform daily ventilation and smoke evacuation in case of fire;

- High opening speed – reaching the maximum opening stroke in no more than 60 seconds from receiving the alarm signal.

In addition to the above, there is also the requirement for a large window opening angle (if small angles are accepted for natural ventilation, smoke ventilation windows must have larger opening angles).

The most commonly encountered window automation systems are chain actuators. Although they have some notable advantages (small size, affordable price, reliability), they also present some disadvantages (limited force to medium values, limited strokes to 1200 mm or even 750 mm for smoke ventilation, noisy operation).

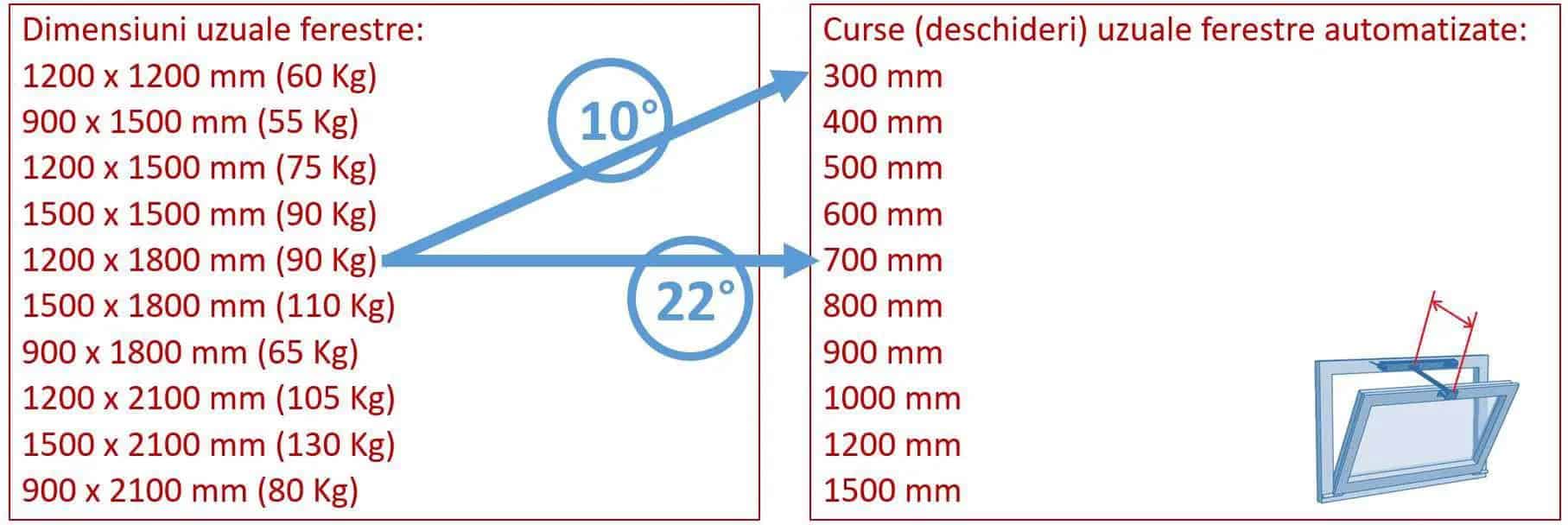

Automatic Window Dimensions

If we analyze the top 5 most common window sizes in office buildings and the top 5 most common chain actuator strokes, we observe that, for larger windows, the most commonly used chain motors for windows allow opening angles of 10-22 degrees.

However, when smoke and hot gases evacuation is necessary, the most requested (by designers, firefighters, fire inspectors, etc.) opening angle is 90 degrees. If we have a window 1.5 m high and 1 m wide, with hinges at the bottom (for example), to open it at 90 degrees, we would need a chain motor with a stroke of 2100 mm and a minimum force of 450 N (without considering wind pressure). Given that chain actuators for smoke ventilation, tested according to EN 12101-2, have strokes of 700 – 750 mm and forces of 200-300 N (rarely 400 N), it is evident that, for certain smoke ventilation windows, the chain actuator cannot be a solution.

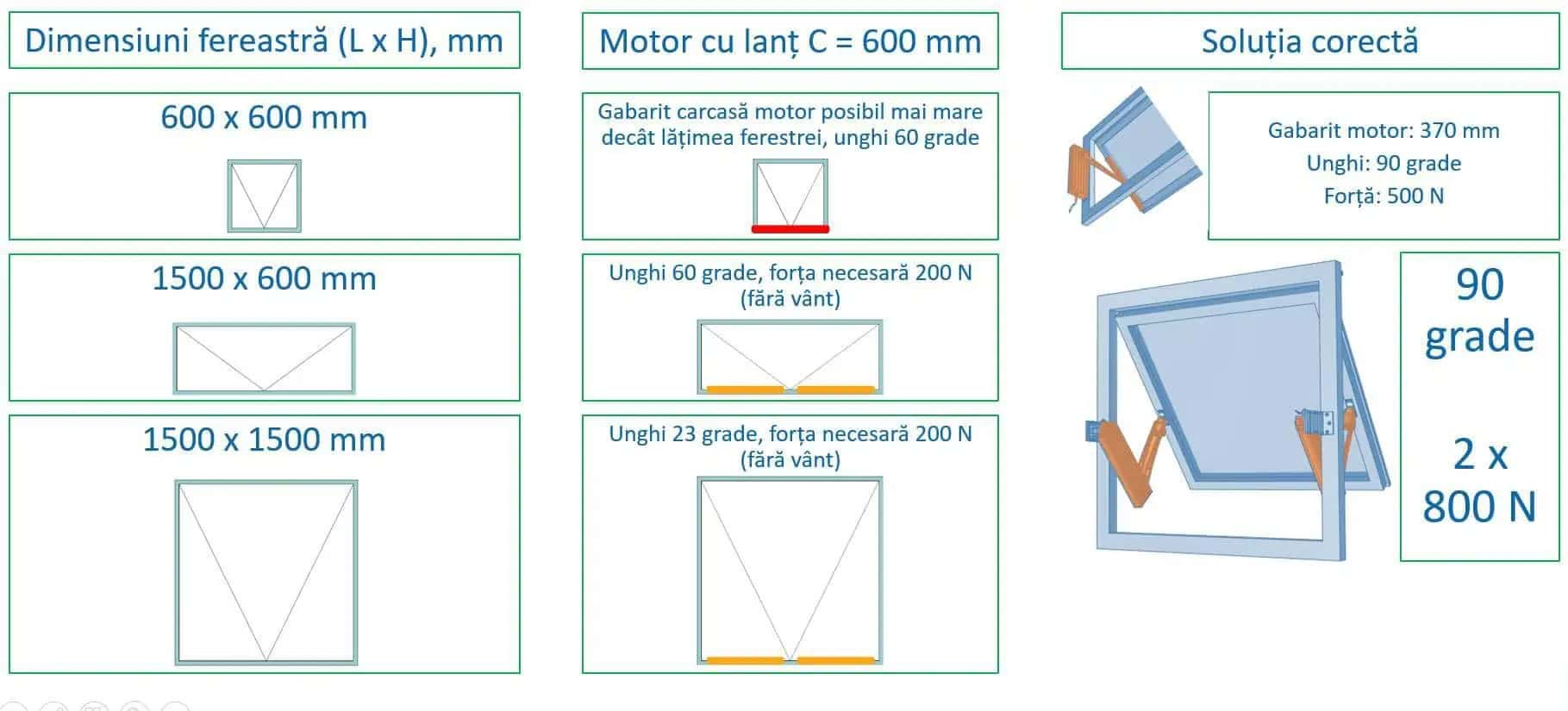

Below are three situations (quite commonly encountered) of smoke ventilation windows with extreme dimensions (very small and very large):

It can be observed that a chain actuator either does not fit (for the small window) or cannot ensure 90-degree openings for larger windows. In the “correct solution” column, the variant that meets the force and opening angle requirements is illustrated: window actuator with articulated arm.

Actuators with Articulated Arm, for Smoke Ventilation Windows

KlappArm articulated arm automation, from SIMON RWA, for windows, comes with several remarkable advantages:

- they are usable for windows with special shapes;

- allow 90-degree openings;

- develop forces of 300, 500, and 750 N – can operate windows up to 1800 x 1800 mm;

- multiple actuators can be synchronized;

- incorporate robust, durable mechanics made of quality steel;

- programming (angle, force) is customizable with the SICO-LINK application;

- can be used both for smoke and hot gas evacuation windows and for fresh air supply windows or doors for smoke ventilation;

- can be mounted both on the closing edge of the window and on the side edges;

- can be used for windows with mixed function – ventilation and smoke evacuation.

Applications of Articulated Arm Actuators

They are very reliable and versatile automation systems and can be used for:

- Rectangular windows of any size (small, medium, large), requiring large opening angles;

- Horizontal roof hatches;

- Windows integrated into skylights, with various inclination angles;

- Doors designed for air intake from outside, for smoke extraction;

- Hatches and access panels (in the attic).

With over 30 years of experience in automating access ways and windows, KADRA offers turnkey solutions for your projects, starting from consultancy in choosing the right solution, through selecting quality products from chosen manufacturers, and ending with associated services of installation, warranty, maintenance, and post-warranty interventions, with qualified and experienced personnel.