Compact Polycarbonate from KADRA

When you want to keep costs under control but it is important to complete all your projects, no matter how bold they are, polycarbonate can prove to be the perfect solution: resistance, versatility, accessibility.

Transparent like glass, compact polycarbonate sheets weigh half as much and are 250 times more resistant to shocks than glass. The sheets also offer the best thermal and acoustic insulation properties.

- VERSATILE – Polycarbonate panels have diverse uses in industry and construction, both for interior and exterior (canopies, pedestrian tunnels, roofs, facades, etc).

- IMPACT RESISTANT – The combined resistance and flexibility make polycarbonate an easy-to-use material for anyone, whether a construction specialist or not.

- TRANSPARENT – Polycarbonate structures allow natural light to enter the space, reducing artificial light sources and ensuring additional visual and thermal comfort.

- LIGHTWEIGHT – Being lighter than glass, it allows much easier installation, both on large and small surfaces, and significantly reduces installation costs.

- UV PROTECTION – The exterior of the sheet is treated with a special polycarbonate that absorbs a large amount of UV radiation. The material does not discolor and retains its resistance, even after prolonged exposure to solar radiation.

Compact Polycarbonate Has Diverse Uses:

- Covering straight or curved canopies

- Covering gazebos

- Windows for agricultural machinery

- Covering courtyards

- Curved closures

- Exterior stair closures

- Protection panels

Characteristics

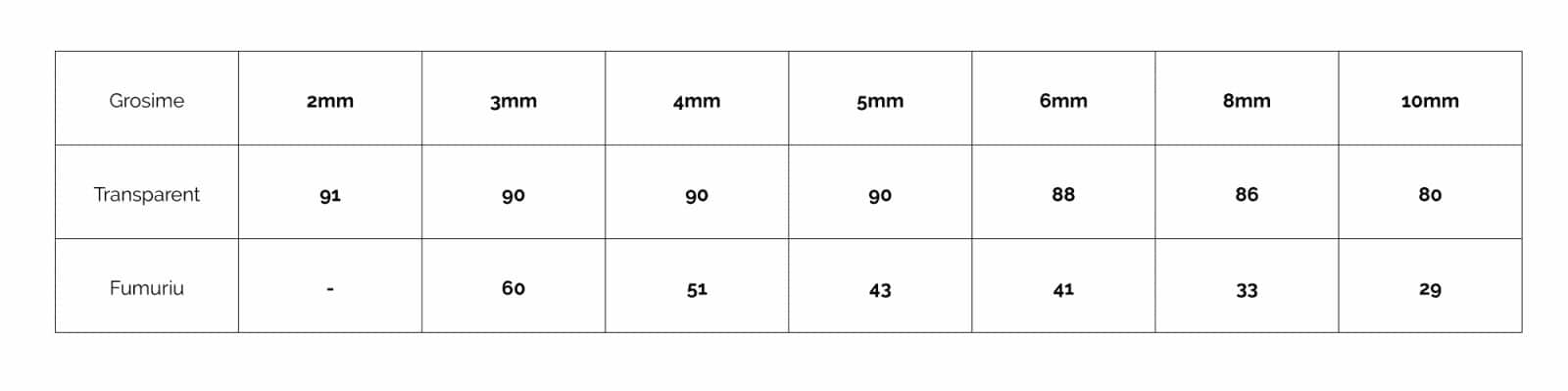

Light transmission %

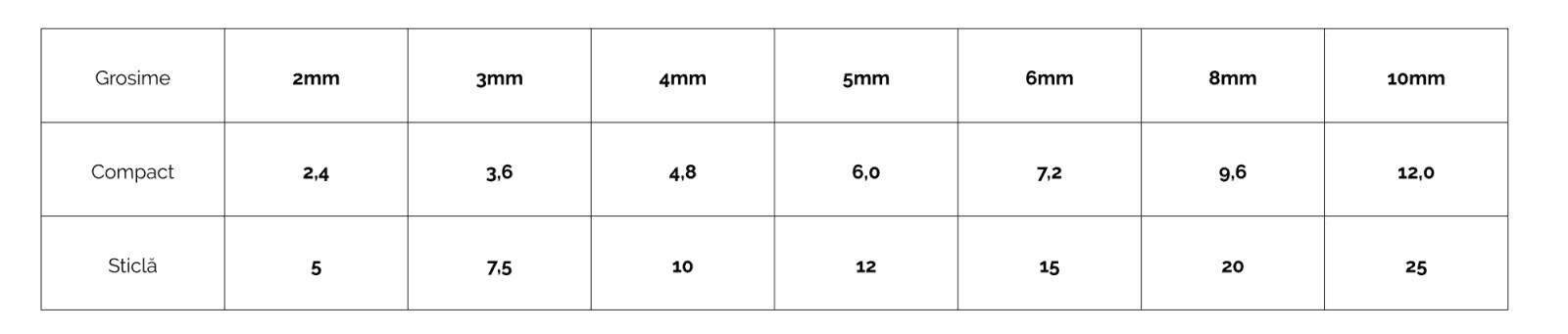

Weight (Kg/m2)

Flat Applications:

Compact polycarbonate sheets can be installed in most structures and frames made of PVC, wood, steel, and aluminum. The frame must keep the sheet fixed while allowing it to expand.

Curved Applications:

The minimum bending radius must be 150 times greater than the thickness of the sheet

Ex. Sheet thickness 3mm. Minimum bending radius = 3×150 = 450mm

Applications in the Medical Field, for Life-Saving Ideas:

The crisis generated by the new coronavirus has severely tested the Romanian healthcare system but has also revealed the creativity and proactivity of many entrepreneurs who found quick and useful solutions for the needs of hospitals.

This is how innovative uses of polycarbonate, adapted to the current situation, emerged.

- VISORS which prove very useful as an additional protective measure for doctors can be successfully made from transparent compact polycarbonate, with thicknesses up to 1mm (sheet size 1250x2050mm).

- DISINFECTANT TUNNELS, lightweight structures equipped with disinfectant solution sprayers, placed in triage or dressing-undressing areas in hospitals, are made from transparent compact polycarbonate, thicknesses of 2 and 3mm, (sheet size 2050x3050mm) OR from transparent cellular polycarbonate, 4mm (sheet size 2100x6000mm).

- ISOLATION CUBES designed to isolate the patient to limit contamination of medical staff (through expiration, coughing, sneezing) are made from transparent compact polycarbonate, thicknesses of 2,3,4,5mm (sheet size 2050x3050mm).