Window Actuators

A component of process automation in modern buildings must be window automation, whether they are natural ventilation windows or smoke extraction windows through organized natural draft.

Window actuators can be operated from a local button or integrated into organized natural ventilation systems, can be integrated into BMS, control units can be equipped with wind, rain, temperature, CO2 sensors (for indoor air quality) etc.

Certain types of window actuators can also be used in building smoke extraction systems in case of fire, through organized natural draft, both for smoke and hot gas evacuation windows and for fresh air intake windows.

Window actuators ensure the safe opening and closing of windows, automatically or at the command of the local user, can ensure automatic opening in case of fire, prevent misuse (thus degradation) of windows and are a modern solution, increasingly widespread in modern buildings.

In terms of operation, the motor receives (from a control unit, from a locally placed button, or from the building’s BMS) a command to open or close the window. Modern actuators, with built-in control module, can communicate bidirectionally with the control system and can be monitored in real-time by it, being directly integrable actuators into BMS.

Window Actuators – Common Types

Below, you will find the most common types of motors for automatic window actuation.

Window actuators:

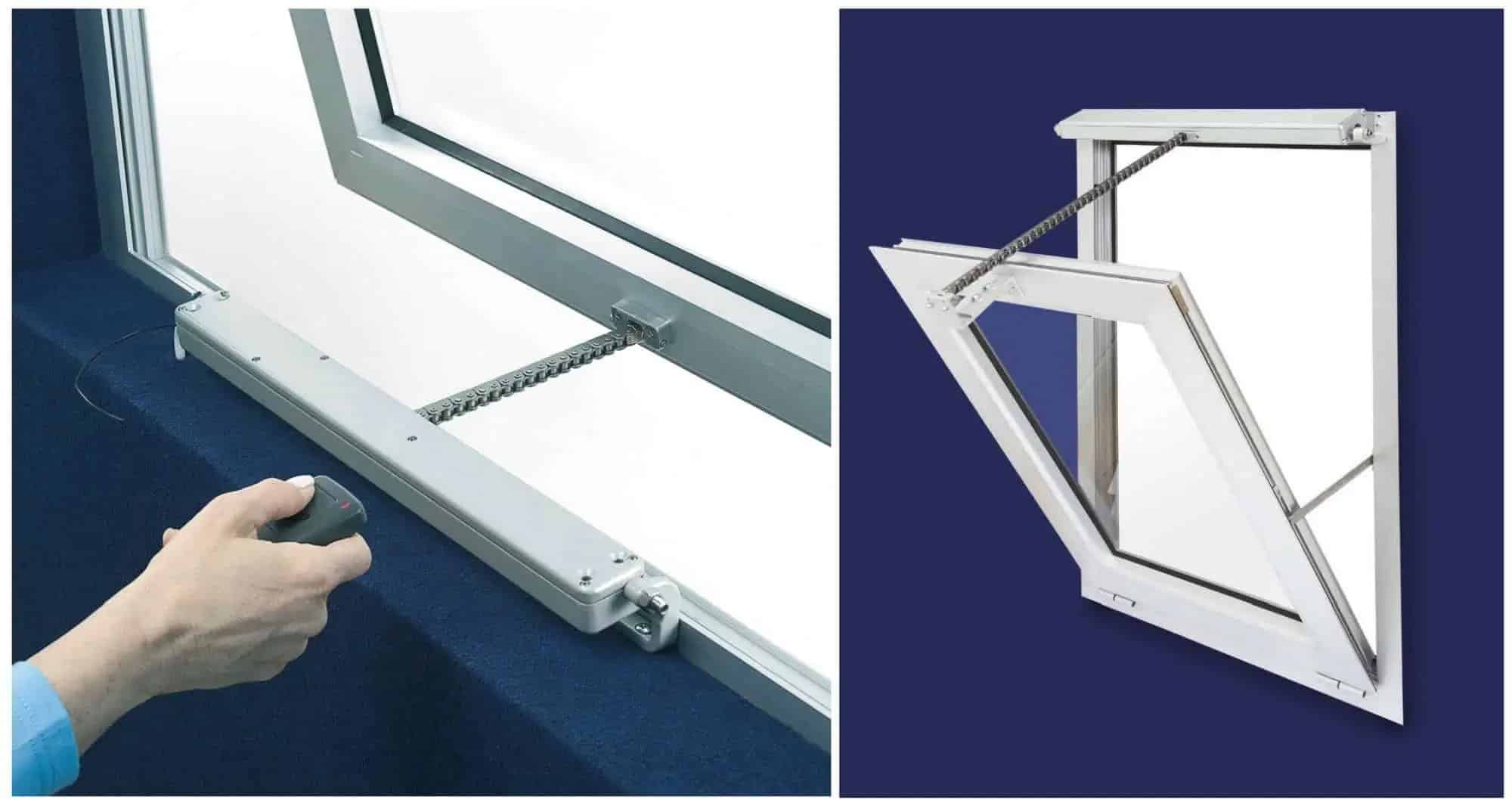

- Chain actuators

- Rack actuators

- Articulated arm actuators

- Rod actuators

- Slot and screw gear actuators

Chain actuators – for windows are the most economical and most commonly encountered variant, especially for standard-sized ventilation windows, when large strokes (opening angles) are not required. They can be mounted on both inward-opening and outward-opening windows, with hinges placed at the bottom, top (with some limitations), or side (with limitations). Generally, they have strokes of 200 – 700 mm (can reach 700 – 1200 mm) and pulling forces of 200-300 N (can reach 400-600 N). For some manufacturers, the pushing force is smaller than the pulling force, and can even be insignificant for large strokes (1000 – 1200 mm).

Rack actuators for windows, due to the pinion-rack gear, allow large opening strokes and larger pulling/pushing forces, up to 1000 N. The pulling force is equal to the pushing force, but rack motors have the disadvantage that they can only be used on outward-opening windows. They are successfully used on roof hatches and can be coupled with 4 motors in a “syncro” system (synchronized operation).

They are recommended when we have large and heavy windows, even horizontal (roof hatches), that require large strokes (larger opening angles).

Rod actuators generally have smaller strokes (200 – 500 mm) and forces up to 650 N. There are variants with higher IP protection rating that can be used outdoors, even for operating external shading systems (external blinds). The motion transmission system does not allow high opening speeds, therefore they are not used for smoke extraction windows. Like rack actuators, rod actuators are used on outward-opening windows.

Articulated arm actuators are window motors with very good performance, ensuring very large opening angles (up to 90 degrees), have forces up to 750 N (1500 N with two synchronized motors) and can be successfully used even on very large or very small windows, where no other type of actuator fits.

They are used on windows with outward or inward opening, with hinges at the top, bottom, or side, and can be mounted both on the closing edge of the window and on the side edges.

For more details, consult the KADRA article about actuators for special windows.

Slot and screw actuators are capable of strokes of 300 – 700 mm and forces of 500 – 750 N. They are a less common solution, but they have the advantage of good performance and it is worth mentioning that they do not change their size during operation. Additionally, they have a reduced size and are aesthetic, making them suitable for more demanding projects.

Smoke Ventilation Window Motor

At first glance, motors for ventilation windows and motors for smoke ventilation windows look similar and can sometimes be confused. There are also projects where, instead of smoke ventilation motors, organized natural ventilation motors are installed. Not infrequently, during the IGSU inspection for building fire safety approval, the replacement of non-compliant motors is requested.

In general, window motors for ventilation are powered at 230V AC, but there are also versions powered at 24V DC. Most ventilation motors have a plastic casing, but some with a metal casing can also be found. The documents accompanying the actuator make the difference. A smoke ventilation window motor will be tested, according to the European standard EN 12101-2, for several essential characteristics for smoke ventilation:

- The ability to reach the maximum stroke in the “open” position within 60 seconds;

- The ability to maintain mechanical stability for 30 minutes at a temperature of 300 degrees Celsius;

- The ability to operate at low temperatures (zero degrees Celsius);

- Durability of (tested at) a minimum of 1000 open/close cycles if used exclusively for smoke ventilation or a minimum of 10,000 cycles if the motor is used for both smoke ventilation and daily ventilation.

If the seller cannot provide documents (test reports, classification reports, issued by a notified body) showing the above characteristics, it is most likely a motor for a ventilation window, which is not suitable for smoke ventilation in case of fire.

KADRA offers you complete and certified solutions for smoke ventilation with organized natural draft, smoke ventilation solutions for staircases, electric or pneumatic smoke dampers, automation for smoke ventilation windows, and our over 30 years of experience is the guarantee that we can advise you on choosing the optimal solution, ensure correct implementation, and offer maintenance and servicing with qualified specialists.